Manufacturing Agreement Template: Essential Contract for Scaling Your Manufacturing

12 Downloads

Commercial, Real Estate

March 8, 2025

Sayantani Dutta

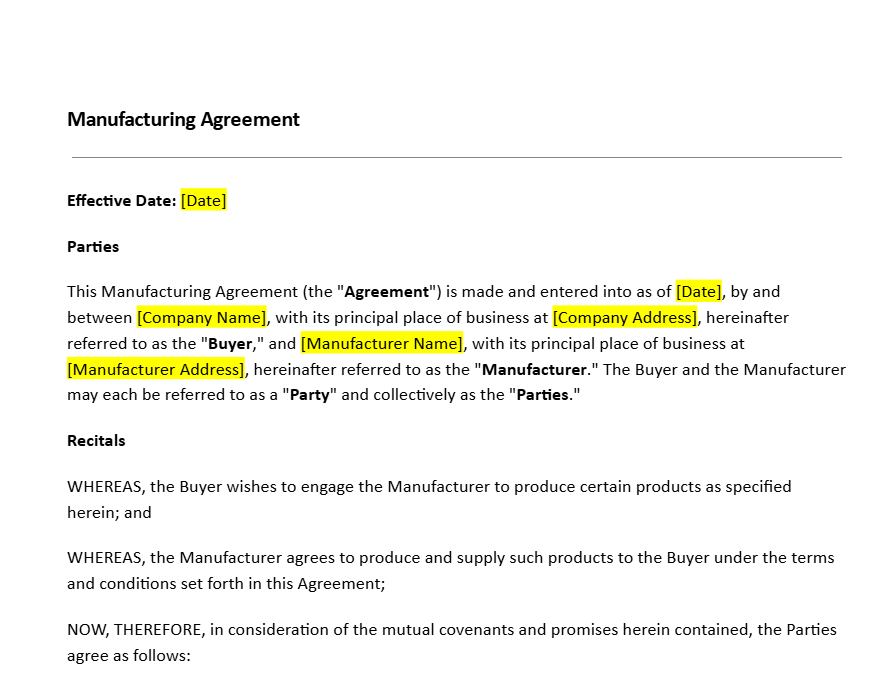

Most product-based businesses do not manufacture everything in-house. Instead, they rely on specialist factories and contract manufacturers to produce their goods at scale. Whenever a company outsources production in this way, a clear and detailed Manufacturing Agreement or Contract Manufacturing Agreement becomes essential. This written contract sets expectations for both the business and the manufacturer, protects their interests and encourages both sides to act in good faith and with reasonable care throughout the engagement.

By signing a structured manufacturing agreement template, a business can legally allow an external manufacturer to produce its products, especially where the business does not have its own plant, machinery or skilled workforce. The manufacturer then produces the products strictly in line with the agreed terms and conditions, while the brand focuses on marketing, sales and distribution. A professionally drafted Manufacturing Agreement Template makes this outsourcing arrangement smooth, scalable, legally enforceable and commercially fair for both parties.

But what exactly is a Manufacturing Agreement? In simple terms, it is a formal, business-to-business contract that governs the manufacture and supply of products. A robust manufacturing contract clearly defines the scope of work, purchase orders, production process, quality checks, supply chain responsibilities, delivery timelines, pricing and payment terms, as well as the rights and obligations of each party. The goal is to safeguard the legitimate interests of both the client and the manufacturer and to address crucial issues such as:

- Ownership and protection of intellectual property and product designs

- Right to use technology, tooling, software and specialised know-how

- Warranty, after-sales support and defect rectification

- Agreed standards of quality and compliance with industry norms

- Minimum and maximum quantities to be manufactured

- Timelines and effective dates for production and delivery during business days

- Force majeure events and impact on obligations

- Severability of clauses to keep the contract enforceable

- Detailed provisions for defective, non-conforming or faulty products

- Provisions for material breach and remedies available to the non-defaulting party

- Provisions for indemnity, limitation of liability and risk allocation

The manufacturing contract may also capture the step-by-step procedure to be followed at each stage of production, inspection, packaging and dispatch of the finished products.

Manufacturing agreement templates allow businesses to scale faster by collaborating with experienced manufacturers who operate as independent contractors or subcontractors. Outsourcing production through a contract manufacturing agreement also helps the client save significantly on capital expenditure, labour costs, utilities, equipment, maintenance and plant management. In international trade and cross-border supply arrangements, this practice is extremely common, which makes it even more important to have a well-drafted manufacturing agreement governed by the correct law and jurisdiction to avoid disputes, penalties and legal uncertainty.

In today’s highly competitive environment, businesses must plan their manufacturing, inventory and supply chain with care if they wish to remain profitable over the long term. A clear, practical and comprehensive manufacturing agreement format is designed keeping these risks and disruptions in mind so that both parties can operate smoothly. A formal document of this nature empowers businesses to:

- Plan and allocate resources more efficiently

- Reduce overall production and transaction costs

- Mitigate operational, legal and reputational risks

- Minimize conflicts of interest between client and manufacturer

- Avoid misunderstandings and communication gaps

- Maintain consistent product quality and brand reputation

- Protect margins and achieve desired profit levels

There is no doubt that well-prepared manufacturing contracts are critical business tools. However, the value they provide depends entirely on how carefully, comprehensively and professionally the agreement has been drafted. Weak, vague or copied clauses can create more risk than protection. This is exactly why many businesses now use expert-developed Manufacturing Agreement Templates as the starting point for all their manufacturing contracts.

Why You Need a Manufacturing Agreement Template

If you are still wondering whether you really need a formal manufacturing agreement template, it helps to think of it as the foundation of your relationship with the manufacturer. When the terms and conditions of the partnership are clearly written and easy to understand, it creates a stable, legally sound framework for a long-term collaboration. Both parties feel accountable, understand their role in dispute resolution, and are more likely to honour their commitments.

A well-planned manufacturing agreement, drafted in line with the applicable governing law, captures critical details of the arrangement, including:

- Design, technical drawings and product specifications

- Purchase order process and approval workflow

- Production timelines, delivery dates and shipment schedules

- Costing, pricing structure, payment terms and taxes

- Quality control, testing procedures and rejection criteria

- Ownership, licensing and permitted use of intellectual property

- Deadlines, milestones and service levels to be maintained

- Confidentiality, non-disclosure and data protection clauses

A standard manufacturing and supply agreement places all important commercial and legal terms on the table in a transparent manner for both the business and the independent contractor. This helps the manufacturing process run in a predictable and controlled way, with balanced rights and obligations. Depending on the term of the agreement, it can reduce legal exposure, keep communication structured and significantly lower the chances of future disputes.

When both partners operate through a written contract manufacturing agreement, they are able to rationalise and often reduce expenses such as:

- Recruiting, training and retaining a full-time labour force

- Sourcing and managing raw materials and consumables

- Training personnel on complex production processes

- Purchasing, leasing or maintaining machinery, tools and equipment

- Factory overheads such as utilities, rent and repairs

- Logistics, distribution and delivery-related inefficiencies

- Legal, attorney and advisory fees linked to unclear arrangements

- Multiple vendors, suppliers and third-party service providers

- Other hidden or unplanned operating costs

A well-structured Manufacturing Agreement Template also sends a strong signal that both parties are serious, professional and understand how to manage manufacturing collaborations. The client gains confidence that the manufacturer knows the expectations, while the manufacturer can work with clarity around pricing, timelines and responsibilities as per the agreed terms.

The agreement also reduces the risk of scope creep, uncontrolled changes in product specifications, and deviations from the original plan. It helps prevent delays, fraud, budget overruns and similar issues. Dedicated provisions can be inserted to handle defective or poor-quality goods, including rework, replacement, credit notes, or refunds, based on what the parties negotiate.

In short, a well-crafted manufacturing contract acts as a blueprint for success and a legal safety net, keeping the arrangement transparent and free from hidden agendas.

Major Components of a Manufacturing Agreement Template

An effective and detailed Manufacturing Agreement Template, customised to the applicable laws of the state or country, brings together several essential components. These elements make the agreement comprehensive, enforceable and commercially practical. They also ensure that the contract protects both sides and remains balanced in its risk allocation.

Some of the key components normally covered in a strong manufacturing agreement format include:

- Parties Involved: This section sets out the full legal names of the parties, their registered and operational addresses, business details, description of the manufacturer’s facilities, contact information and any group entities or affiliates involved in the arrangement.

- Product Specifications: Here the agreement explains exactly what is to be manufactured. It may refer to annexures or schedules that contain detailed product drawings, technical specifications, bill of materials, approved raw materials, technology to be used, packaging standards and expected quality benchmarks.

- Pricing and Payment Terms: This section defines the commercial backbone of the contract. It usually specifies unit prices, volume-based price breaks, cost escalation clauses, taxes, duties, advance payments, credit periods, penalties, and the method and timeline of payments.

- Delivery Schedule: Delivery-related clauses set out production deadlines on business days, lead times, shipment schedules, Incoterms (for international trade), place of delivery, responsibilities for freight and insurance, and consequences of delayed or partial delivery.

- Quality Control: Since quality is central to any manufacturing agreement, this section covers testing procedures, sampling plans, inspection rights, acceptance and rejection protocols, corrective action plans, and the standards or certifications that the products must comply with.

- Intellectual Property Rights: To avoid disputes around IP ownership, this part of the manufacturing contract clarifies who owns the designs, drawings, trademarks, patents, software and trade secrets. It may also grant limited, non-transferable licenses to the manufacturer purely for producing the client’s products.

- Confidentiality Clause: This section explains how confidential and sensitive information will be handled. It usually governs non-disclosure, restrictions on sharing information with third parties, data security practices and consequences if confidential information is misused or leaked.

- Termination Clause: The termination section sets out the grounds on which either party can terminate the manufacturing agreement, such as insolvency, repeated breach, non-payment, failure to meet quality standards, or force majeure events. It should also explain what happens on termination, including return of materials, settlement of dues and transition support.

- Signatures: Finally, the agreement must provide space for signatures of authorised signatories of both parties, including name, designation and date. These signatures confirm that both parties have read, understood and accepted the terms and conditions contained in the manufacturing agreement.

Manufacturing Agreement Template: Consequences of Not Using a Contract

When a business starts manufacturing through an external vendor without a written manufacturing agreement or at least a clear manufacturing agreement template, both parties expose themselves to avoidable risks. In the absence of a legal document, important terms may be discussed informally but never recorded. Over time, this leads to confusion, disagreements and misaligned expectations, which in turn can cause delays, cost overruns, loss of customers and even serious legal disputes.

If you are still evaluating whether to formalise your manufacturing relationship through a proper contract, here are some of the most common risks associated with not using a manufacturing agreement format:

1. Issues with Ownership Rights

Without a written manufacturing contract, both sides may assume that they own or can freely use the designs, moulds, technical drawings or brand names involved in the production. This can trigger conflicts around intellectual property, as neither party has a clear written record of the licence or ownership of such rights. In extreme cases, it may result in unauthorised use of trade secrets, trademarks, copyrights or patents, exposing both sides to expensive litigation.

2. Vague Product Specifications

If specifications are discussed only verbally or over email and are not consolidated in a formal manufacturing agreement, the manufacturer may reasonably interpret the requirements differently from what the client intended. The absence of documented quality standards, testing procedures and acceptance criteria can lead to substandard or defective products, rework, wastage and strained relationships with end customers.

3. Unclear Expectations

A missing or incomplete manufacturing agreement often means that crucial responsibilities are not properly allocated. It becomes unclear who is responsible for sourcing raw materials, handling import duties, arranging logistics or obtaining regulatory approvals. This lack of clarity leads to delayed deliveries, disputes on payment obligations, non-compliance with laws and possible penalties, all of which can damage the reputation of both the brand and the manufacturer.

4. Legal Disputes

While some jurisdictions may recognise implied contractual obligations, the absence of a signed manufacturing contract template makes it much harder to prove what was agreed if a dispute arises. There may be nothing to show that both parties understood and accepted the same terms. This can lead to legal battles around non-performance, cancellation of orders, early termination or alleged fraud. Such disputes are not only time-consuming and costly but may also disrupt the entire supply chain and cause serious business setbacks.

Streamline Your Production With FreshDox’s Manufacturing Agreement Template

A well-designed Manufacturing Agreement Template, backed by expert legal insight, is much more than a standard form. It is the foundation on which your outsourced manufacturing, brand reputation and long-term business partnerships are built. Whether you are a fast-growing start-up or an established enterprise, a robust manufacturing contract can significantly improve visibility, control and profitability across your production lifecycle.

However, drafting such an agreement from scratch can be challenging if you or your team do not have the time, legal background or in-house documentation expertise. This is where FreshDox.com can be a practical ally. FreshDox provides premium-quality, expert-reviewed business and legal document templates, including a professionally structured Manufacturing Agreement Template that you can adapt quickly to your specific products, industry and jurisdiction.

Each FreshDox template is thoughtfully crafted by experienced legal professionals and subject-matter experts. The manufacturing agreement format available on FreshDox covers key clauses around product specifications, pricing, quality, IP rights, confidentiality, termination and dispute resolution, helping you avoid common drafting gaps. As a Basic or Premium member of FreshDox, you can access a wide library of certified and standardised templates that can be downloaded in both Word and PDF formats for instant editing, approval and sharing with your stakeholders.

FreshDox also offers a 14-day trial period, allowing you to explore the benefits of our Basic and Premium plans. Basic Members can download up to three document templates every month, while Premium Members enjoy access to unlimited downloads—ideal for businesses that regularly execute contracts, policies and internal documentation.

If you are serious about protecting your brand, reducing legal risk and streamlining your manufacturing process, now is the right time to move away from generic samples and adopt a trusted manufacturing agreement template from FreshDox.com. Subscribe today, download the Manufacturing Agreement Template, customise it for your products and partners, and manage your production like a true professional.

Popular searches:

- Manufacturing Agreement Template: Essential Contract for Scaling Your Manufacturing pdf

- Manufacturing Agreement Template: Essential Contract for Scaling Your Manufacturing sample

- Manufacturing Agreement Template: Essential Contract for Scaling Your Manufacturing download

- Manufacturing Agreement Template: Essential Contract for Scaling Your Manufacturing format

- Manufacturing Agreement Template: Essential Contract for Scaling Your Manufacturing template

- Manufacturing Agreement Template: Essential Contract for Scaling Your Manufacturing word

- Manufacturing Agreement Template: Essential Contract for Scaling Your Manufacturing free

Related Templates

Discover more templates that align with your needs and preferences.

Ready to Sign Up?

Sign up for FreshDox.com’s 7-day trial and discover why so many individuals and businesses trust us for their legal document template needs.

- Cancel any time

- 7-day free trial

- From 300+ Customer Reviews